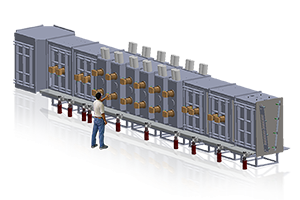

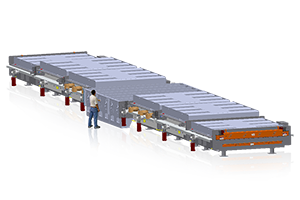

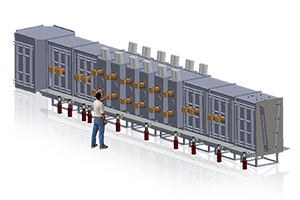

Mustang’s industrial vacuum deposition systems are optimized for the unique challenges of the latest generation of thin film photovoltaics.

Utilization, Uptime, and Yield – Delivering truly high yield vacuum deposition systems requires the careful consideration of not only source utilization but optimizing preventative maintenance cycles and simple robust substrate loading. The largest impact on manufacturing throughput is scheduled down time. Production uptime is most severely impacted by the frequency of source material changes, substrate load and unload cycles and the time and resources to complete scheduled maintenance. Mustang Solar designs and engineers our systems to balance these factors to achieve unparalleled uptime and throughput.

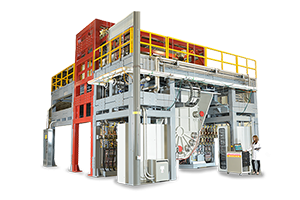

CIGS Applications

Back Contact | Front Contact | Buffer Layer | Absorber | Solar Tools

Other PV Applications

Mustang’s Solar division continues to drive industrial scale performance for the next generation of thin film PV materials. We provide vacuum deposition solutions for both pilot and production scale manufacturing. Mustang Solar routinely collaborates with customers to help select and optimize deposition sources, system architecture and manufacturing line optimization to ensure these latest technologies achieve the highest levels of uniformity and manufacturing uptime.

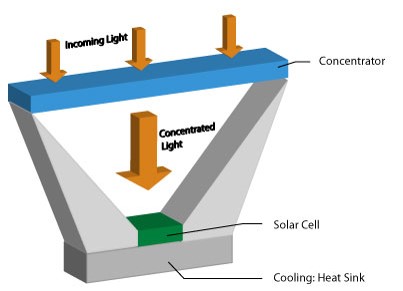

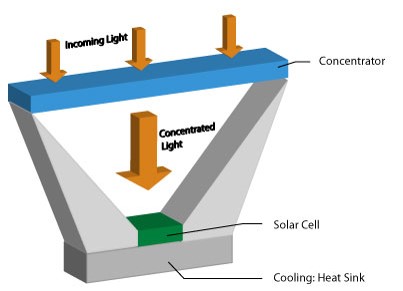

Concentrated Photovoltaic (CPV) Solar Applications

- CPV Thermal Systems use solar energy to super heat liquids for hot water heating and in large applications for steam generation to power turbines.

- CPV Solar cell Systems use reflectors to concentrate solar light onto a high efficiency solar cell increasing dramatically the amount of power per solar cell.

- A number of thin film coatings to apply highly reflective metals such as aluminum, enhanced aluminum and silver to reflectors made from glass, metal and plastics. Sealed CPV arrays also can use optical filter coatings and moisture barrier layers to improve life or performance. Mustang Solar has experience in a range of materials for these applications providing both coating services and production equipment for the next generation of CPV power generation.

CdTe Cadmium Telluride Photovoltaics

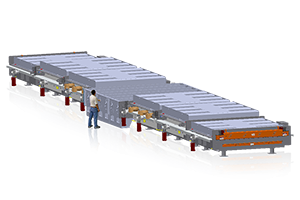

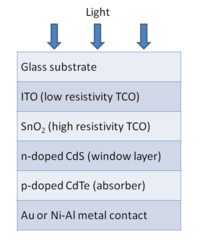

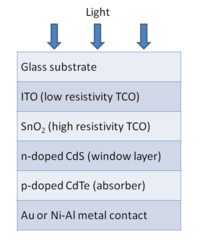

Cadmium telluride (CdTe) photovoltaics describes a photovoltaic (PV) technology that is based on the use of cadmium telluride, a thin semiconductor layer designed to absorb and convert sunlight into electricity. This multi-layer is typically deposited on a superstrate of glass which becomes the front side of the cell with layers of ITO, SnO2, CdS, CdTe and finally NiAl are applied to make a complete cell. Each of these layers are deposited by PVD Physical Vapor Deposition in a vacuum environment. Mustang Solar Horizon series of high speed glass deposition systems range from Pilot to full manufacturing scale.

Recommended Equipment: